Semi Trucks

Logistics

Lease & Maintenance

Buy Used Trucks

Key Takeaways:

Businesses face unprecedented challenges in today’s unpredictable transportation landscape.

Companies must overcome hurdles such as volatile freight rates, escalating equipment costs, geopolitical disruption, and the ever-present pressure to reduce risk while ensuring service continuity.

As the complexity of transportation logistics continues to grow, the need for integrated, resilient, and responsive supply chains is increasingly critical.

Here, we’ll explore how partnering with third-party logistics providers (3PLs) like Ryder offers companies the flexibility and control they need to thrive amidst uncertainty.

Current Transportation and Logistics Market Challenges

The transportation and logistics market is currently navigating a complex landscape filled with numerous challenges that can significantly disrupt operations and affect profitability.

Here’s a more detailed look at these challenges.

Freight Rate Volatility

Freight rates are subject to rapid changes due to factors such as supply and demand imbalances, geopolitical events, and natural disasters.

This volatility is further exacerbated by fluctuating fuel prices, which are influenced by global oil markets, environmental policies, and regional conflicts.

Such unpredictability makes it difficult for companies to forecast costs accurately and plan their budgets effectively.

Rising Equipment Costs

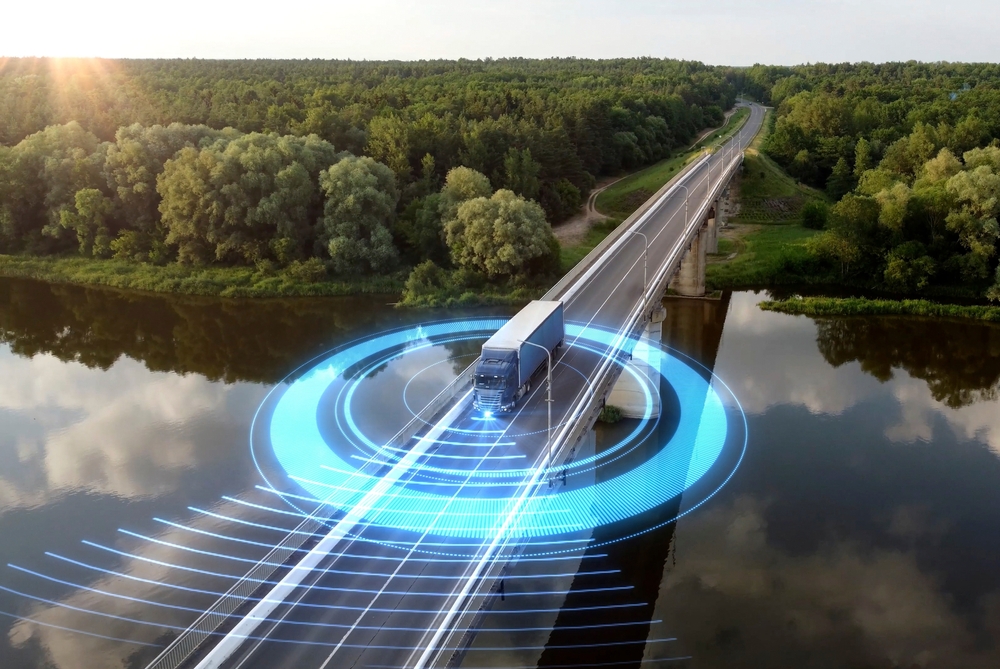

The cost of acquiring and maintaining transportation equipment is on the rise. New trucks, equipped with advanced technology for safety and emissions compliance, are more expensive.

Additionally, maintenance costs are increasing due to the complexity of modern vehicles and the need for specialized parts and labor. This puts a strain on capital expenditure and operational budgets.

Driver Hiring & Retention

The industry continues to grapple with a shortage of qualified drivers, driven by an aging workforce, high turnover rates, and the demanding nature of the job.

Recruiting and retaining drivers is challenging–companies must offer competitive wages, benefits, and working conditions. The shortage can lead to service delays and increased labor costs.

Increased Risk and Liability

With more stringent requirements, nuclear verdicts, and complex logistics networks, the risk of non-compliance, accidents, and operational failures increases.

Companies must invest in risk management strategies, insurance, and technology to mitigate these risks, adding to their operational burdens.

Supply Chain Disruptions

Global supply chains are vulnerable to disruptions from events such as pandemics, supply shortages, port labor disruptions, and natural disasters.

These disruptions can lead to delays, increased costs, and the need for contingency planning.

Technological Integration

While technology offers solutions to many logistical challenges, integrating new systems such as automation, IoT, and AI into existing operations can be complex and costly.

Companies must balance the benefits of technology with the challenges of implementation and training.

In sum, the primary challenge for transportation and logistics companies is to maintain control over their operations while navigating these multifaceted issues.

Leveraging a third-party logistics provider is a smart way to adapt to changing conditions without owning every aspect of the logistics process and the associated costs.

The Case for Partnering with a 3PL

Efficient logistics management is crucial for companies that want to maintain a competitive edge.

A comprehensive 3PL solution offers a wide range of services that go beyond basic transportation and warehousing, providing strategic value and operational efficiency. By leveraging the expertise and resources of a 3PL, companies can enhance their logistics capabilities without the burden of significant capital investment.

A complete 3PL solution encompasses fleet management, dedicated transport, technology platforms, and warehouse integration.

Fleet management ensures that vehicles are well-maintained and operated efficiently, allowing businesses to benefit from optimized routing and scheduling without owning a fleet.

Dedicated transport services provide tailored solutions to meet specific delivery needs, ensuring reliability and consistency.

Advanced technology platforms, such as transportation management systems and warehouse management systems, offer real-time visibility and data-driven insights, enabling better decision-making and improved customer service for your business. Warehouse integration ensures seamless inventory management and order fulfillment, reducing lead times and enhancing service levels.

Partnering with a 3PL means companies gain strategic value and control without the capital expense of owning assets. The benefits are numerous: consistent service levels, access to top-tier technology such as real-time visibility, pricing predictability, scalable capacity, reduced liability, and proactive risk management.

These advantages allow businesses to focus on their core competencies while the 3PL handles the complexities of logistics.

This partnership not only enhances operational efficiency but also positions companies to adapt quickly to market changes and customer demands, ultimately driving growth and success.

Use Case #1: Hill’s Pet Nutrition – Delivering 132 Million Pounds of Pet Food With Precision

Hill’s Pet Nutrition faced the challenge of managing high-volume, high-touch deliveries, with 45,000 shipments per month to sensitive recipients like veterinary offices. They wanted to partner with a company that could help them grow, plus invest in a transportation network that could handle their heavy volume.

For Hill’s, there was only one choice: Ryder.

Ryder offers Hill’s a comprehensive transportation solution featuring over 100 vehicles and more than 200 skilled drivers, along with services such as network design, routing, scheduling, and proprietary technology. This adaptable transportation solution also includes the management of shuttle runs and drayage for Hill’s.

Reflecting Hill’s high-quality products, Ryder drivers deliver a premium white glove service, completing over 45,000 deliveries each month and transporting approximately 132 million pounds of pet food annually. The partnership expanded in 2024 when Ryder took on the management of a Hill’s warehouse facility in Nashville, Tennessee.

In addition to a dedicated fleet, Ryder utilizes RyderShare™ for real-time visibility. The integration of warehouse and transportation services resulted in a 99% on-time delivery rate with a seamless transition, which included many drivers retained from Hill’s. The scalable and responsive logistics system enabled data-driven improvements and daily optimizations. As Hill’s noted, “Ryder is bought into the success of our business, and it shows.”

Use Case #2: Southern Glazer’s – Transforming Inbound Freight Visibility

Southern Glazer’s Wine & Spirits, a leading beverage alcohol distributor, partnered with Ryder to transform its supply chain through enhanced inbound transportation and the implementation of RyderShare™, a cutting-edge visibility and collaborative logistics platform.

This initiative significantly improved visibility, accountability, and efficiency across Southern Glazer’s supply chain, revolutionizing operations and collaboration with suppliers and carriers.

Southern Glazer’s, which represents over 1,700 suppliers and distributes more than 7,000 brands across multiple markets, faced challenges in tracking and monitoring goods, leading to delivery delays and customer dissatisfaction. In 2015, after unsatisfactory results with a previous third-party logistics provider, Southern Glazer’s turned to Ryder, a long-time partner in fleet leasing and maintenance, to address these issues.

Ryder’s solution involved restructuring inbound transportation and implementing RyderShare, providing real-time visibility and collaboration throughout the supply chain. This system allowed Southern Glazer’s to track freight from purchase order to delivery, addressing previous visibility gaps and improving on-time deliveries to over 98% while reducing demurrage and detention fees.

RyderShare also provided granular visibility into multi-leg moves, enabling Southern Glazer’s to optimize operations and reduce fees. The partnership with Ryder has not only enhanced Southern Glazer’s supply chain efficiency but also allowed the team to concentrate on managing strategy instead of chasing freight.

As Southern Glazer’s aims to become the hospitality industry’s most valued logistics provider, Ryder’s expertise and commitment to evolving solutions will be crucial in achieving this vision. “The Ryder team does a great job of navigating the journey with us as a partner with shared goals.”

Why Predictable Pricing and Performance Matter Now More Than Ever

In an era of rising costs and market instability, predictability in pricing and performance is not just a luxury—it’s a survival tool.

3PL partnerships enable companies to lock in reliable service without the burden of asset ownership. Both Hill’s and Southern Glazer’s experienced improved financial planning and reduced operational risk with Ryder’s help, highlighting the importance of predictable logistics solutions.

How a 3PL Becomes an Extension of Your Business

A 3PL is more than just a service provider–it acts as a strategic partner that integrates deeply into your business operations. This partnership goes beyond transactional interactions, as the 3PL becomes an extension of your company, aligning its goals and processes with yours to drive mutual success.

One of the key aspects of this partnership is the presence of embedded teams. These dedicated groups of professionals from the 3PL work closely with your internal teams to ensure seamless integration and communication. This close collaboration allows for a deeper understanding of your business needs and challenges, enabling the 3PL to tailor its services to better support your objectives.

Shared Key Performance Indicators (KPIs) are another critical component of this relationship. By establishing common goals and metrics, both parties can measure success in a unified manner. This alignment ensures that the 3PL is not only meeting its contractual obligations but is also actively contributing to the overall success of your business.

Co-developed innovation is a hallmark of a successful 3PL partnership. By working together, your company and the 3PL can identify opportunities for improvement and innovation within the supply chain. This collaborative approach fosters creativity and leads to the development of new solutions that can enhance efficiency, reduce costs, and improve service levels.

Ongoing collaboration is maintained through structured feedback loops and advisory boards. Regular feedback sessions allow both parties to discuss performance, address any issues, and explore new opportunities for improvement. Advisory boards, which may include representatives from both your company and the 3PL, provide strategic oversight and guidance, ensuring that the partnership remains aligned with long-term business goals.

The importance of cultural fit and partnership dynamics cannot be overstated. Successful 3PL partnerships, as demonstrated in the case studies of Hill’s and Southern Glazer’s, are built on a foundation of trust, mutual respect, and shared values.

These elements create a strong partnership dynamic that enables both parties to work together effectively and adapt to change.

The Future Belongs to the Flexible

In today’s complex logistics environment, complete solutions from 3PLs enable companies to do more with less. Greater visibility, predictable service and pricing, and scalable infrastructure without capital investment are the results of strategic 3PL partnerships.

As businesses navigate the challenges of modern logistics, the decision to partner with a 3PL should be reframed—not as outsourcing, but as upgrading to a more efficient and effective logistics strategy.